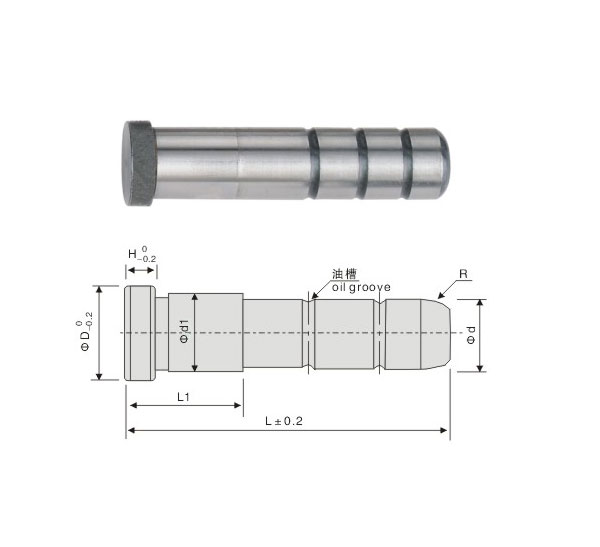

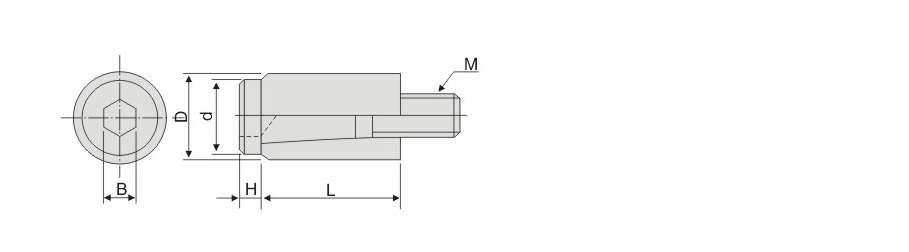

| Catalog No. | d | H | L | M | B | |

| Type | D | |||||

| JH060 | 10 | 8.5 | 3 | 18 | M5 | 4 |

| 12 | 11 | 3.5 | 20 | M6 | 5 | |

| 13 | 11 | 3.5 | 20 | M6 | 5 | |

| 16 | 14 | 4 | 25 | M8 | 6 | |

| 20 | 16 | 5 | 30 | M10 | 8 | |

Order:Catalog No.DxL

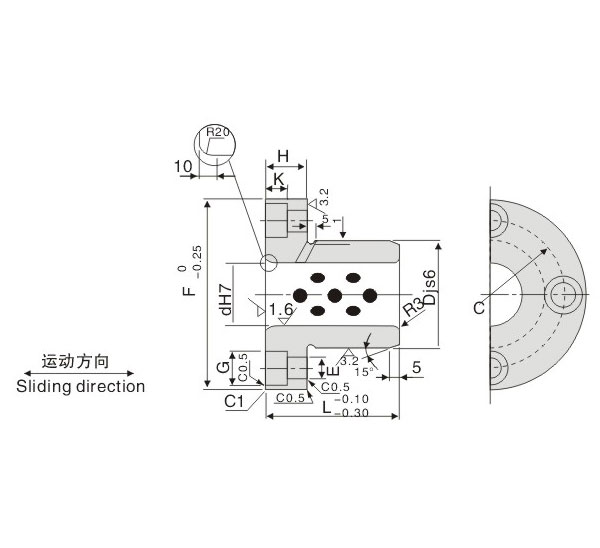

Features:

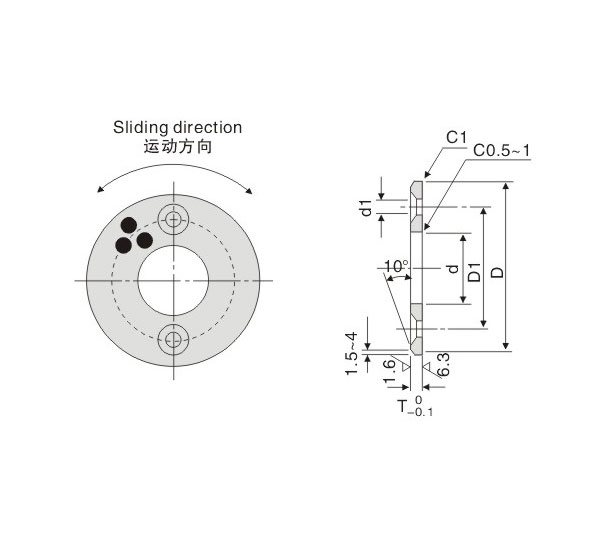

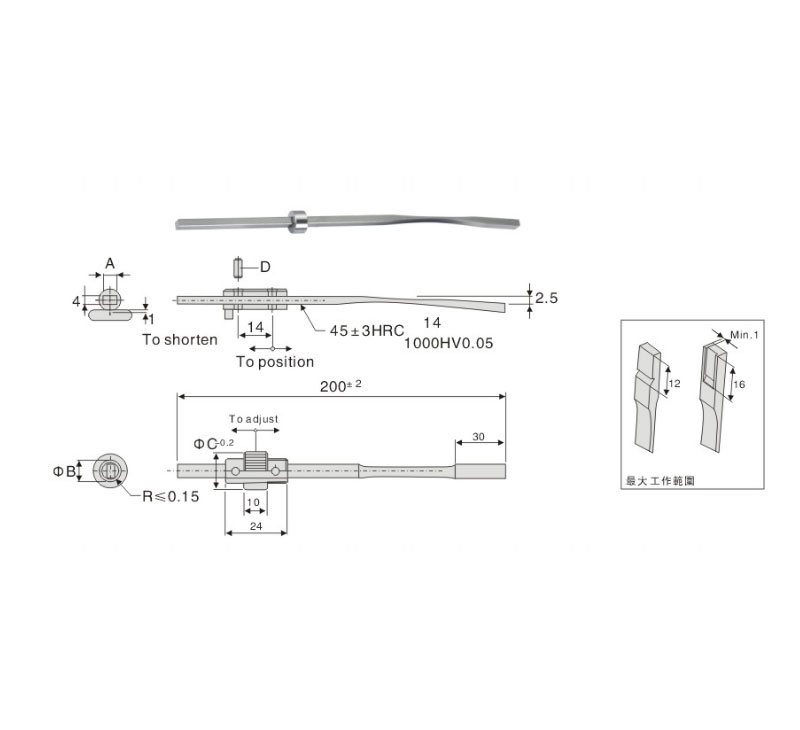

• Use sloping screw to adjust mold plate and parting locks, then turn 90 degrees parting locks can be closed upto 50 ,000 times.

• Easy to assemble and disassemble, and cost efficient.

• Can also be installed into small, medium size, and 2- sectional injecting metal pipes, or can be installed on sliding bases.

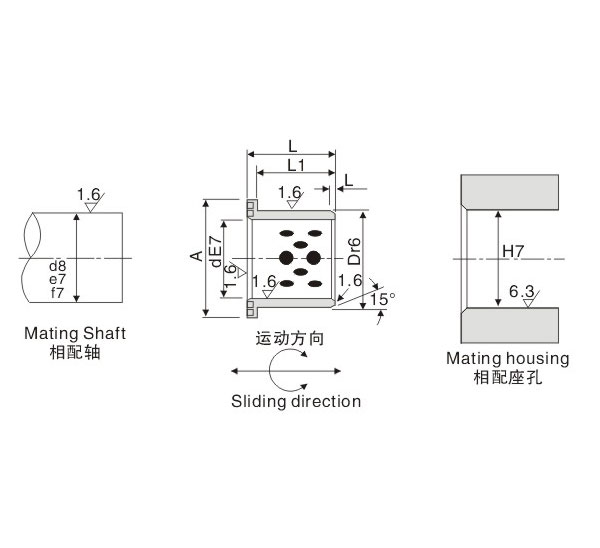

• Mold weight 100kg, using 4pcs of 12Φ. Mold weight 500kg, using 4pcs of 16ΦMold weight 1000kg, using 4pcs of 20Φ.

Mold weight 1000kg, using at least 6pcs.

• Insert parting locks into die mold about 3cm, the using H7 reamer to process mold hole within+0.1mm range.

• Process mold surface to the shape of letter"R"", if processing to the chamfering of letter"C" it will shorten it's life cycle.

• Do not add any oil on paring locks, doing so will reduce the friction.

English

English Le français

Le français España

España lingua italiana

lingua italiana